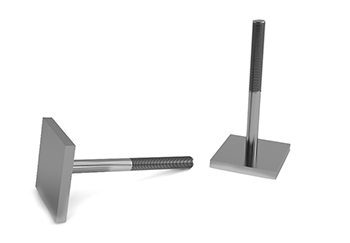

Tie Back Anchors are engineered to provide secure and dependable support for refractory linings in high-temperature industrial applications such as furnaces, kilns, and reactors. The tie back design ensures excellent mechanical interlocking with the refractory material, providing stability, uniform load distribution, and minimal displacement under extreme thermal and mechanical stress.

These anchors are manufactured from high-quality materials, including stainless steel grades (SS 304, SS 304L, SS 310, SS 310S, SS 316, SS 316L, SS 321), nickel alloys (Inconel, Incoloy, Hastelloy), and mild/alloy steel. The precision-engineered design allows for easy installation, strong bonding with refractory linings, and exceptional resistance to corrosion, oxidation, and high temperatures.

Navkar Precision Fittings applies strict quality control and precision engineering to deliver Tie Back Anchors that are durable, reliable, and long-lasting. These anchors are ideal for industrial environments requiring strong, precise, and high-performance refractory anchoring solutions.

| Material Type | Details |

|---|---|

| Stainless Steel | SS 304, SS 304L, SS 310, SS 310S, SS 316, SS 316L, SS 321 – suitable for general-purpose and moderate to high temperatures |

| Nickel Alloys | Inconel 600, Inconel 625, Incoloy 800, Hastelloy – ideal for extreme temperatures and corrosive environments |

| Mild & Alloy Steel | For moderate temperature applications |

| Parameter | Specification |

|---|---|

| Anchor Rod Diameter | 6 mm – 12 mm |

| Anchor Length | 75 mm – 500 mm (customized per refractory lining thickness) |

| Surface Finish | Mill finish / pickled & passivated |

| Installation Type | Stud-welded, tack-welded, or threaded options available |

Powered by Navkar Precision Pvt Ltd | Designed and Developed By Skytech Seo Solutions LLP